What is the difference between air and glycol towers?

Posted by Ron on 23rd Sep 2019

If you've been caught up in the glycol vs. air-cooled beer tower dilemma, the best way to approach it would be to consider your current draught beer dispensing setup and what you want to achieve. In this article you'll find all the information you need to make the right choice and get the most out of your draught beer tower.

Air-Cooled Beer Towers

It’s all in the name, really. As the name suggests, air-cooled beer towers use cold air to push the beer from the keg to the faucet - that’s about as simple as it gets.

Easy to use and relatively cheap, air-cooled towers are most commonly used with direct-draw draft beer dispensing systems. WIth this type of system your keg refrigeration unit should be right next to the point of service - e.g., under the counter.

This makes an air-cooled beer tower system ideal for use with kegerators in small bars and restaurants that:

- do not have a designated space for a full-size walk-in cooler

- offer a limited number of beers (3-5)

- do not have the need to set up a long-draw beer draught system

The cost of an air-cooled beer tower is relatively low (usually starting around $80), making them a great starting point for most beer enthusiasts or restaurant owners.

Options to consider when choosing an air-cooled beer tower:

- Number of faucets

- Style (T-tower, draft arm, etc.)

- Material and finish (typically stainless steel with a variety of finishes - chrome, brass, etc.)

Glycol-Cooled Beer Towers

Again, as the name suggests, this type of tower is designed to be used with a beer glycol cooling system. Glycol itself is a widely popular food-grade refrigerant and a key component of a glycol draft beer system.

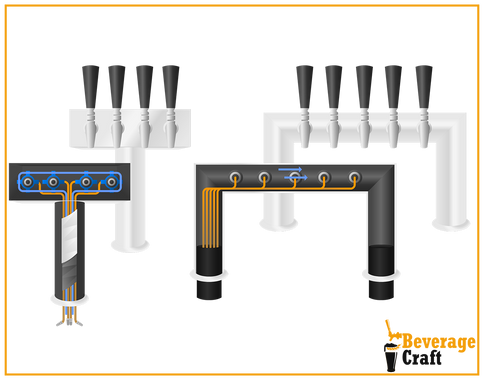

The idea behind this system is that you have a closed circuit of glycol lines (typically 1 or 2) bound to several beer lines into what’s collectively known as a trunkline. As the beer flows from the keg to the dispenser inside a trunkline, it maintains a stable temperature and does not form any foam.

At the front end of this system is a glycol beer tower where the beer is dispensed. Glycol-equipped towers are fit with an aluminum cooling block attached to each of the faucet shanks inside the tower.

Glycol-cooled towers (as well as glycol draught beer systems in general) are typically used when the walk-in cooler is located rather far from the point of service (generally 25 feet or more).

This type of dispensing setup is called a “long-draw draught beer system” and it works great for large bars, pubs, and restaurants serving multiple styles of beer (10 or more).

Which Draught Beer Tower Cooling System to Choose?

Your choice of draft beer tower cooling system mostly depends on a few things:

- your current beer dispensing setup

- how far your beer keg is from the dispenser

- how many different styles of beer you are planning to dispense

- what you are planning to achieve with it

If you run a small bar or simply want to enjoy a fresh, cold beer at home once in a while, you should go with an air-cooled beer tower. It’s easy to use and relatively cheap.

If you own a full-sized pub or restaurant with a walk-in cooler that’s more than 25 feet away from the bar area, installing a glycol draught beer system with a glycol-cooled beer tower(s) is best.